Fully Automatic Crusher

500-200M4 2PLUS

- Overall dimesion : 5500 x 2000 x 2400h mm

- Total weight: 1650 Kg

- Elettrical power: 9,5kW – 380/400V – 50/60Hz

- Productivity: 4 – 5 m³/ hr

- Loading hopper: 500 x 500 mm

- Crushing chamber: 500 x 190 mm

1° binary: 500 x 130 mm

2° binary: 500 x 190 mm - Jaw adjustment: 9 levels [for each track]

- Output size:

1° binary → 0 – 30/40 mm

2° binary → 0 – 60/80 mm - Screening (mm) : 4 Separator (customizable)

Conveyor belt PLUS

- Overall dimensions: 3000/5000 x 550 mm (height: adjustable)

- Loading hopper: 650 mm

- Belt width: 350 mm

- Belt thickness: 15 mm

- Electrical power: 0.75/1.50 kW – 380/400V – 50/60Hz

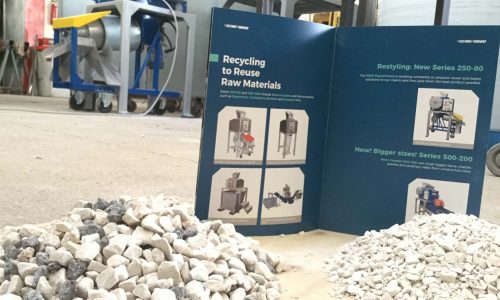

Benefits

The 500-200M4 2PLUS-X model is an integrated automatic system composed of the Crusher, a 4-output Separation System, a loading belt complete with a sensor, and a discharge belt. It is a "circular system" as it eliminates the undesired crushed output by repeatedly performing the crushing phase to ensure that the material doesn't become too fine. This allows for: - The automatic management of the process without any physical effort during the loading phase, where the quantity of "input" material is managed by a detection sensor in proportion to the crushed "output" material. - The achievement of the desired crushed output without any waste. Two conveyor belts are used: one for transferring the input material into the crushing process, and another for passing the undesired material back into the cycle. They feature a reinforced structure in bent sheet metal, painted with rustproof paint and a color suitable for the crushing plant, and the rubber belt between the rollers is suitable for transferring the rocky material across its range.

Assemble your machine

Standard Crusher

500-200

Overall dimensions: 1180 x 980 x 2150h mm

Total weight: 1060 Kg

Electrical power: 5.5 kW – 380/400V – 50/60Hz

Productivity: 4 – 5 m³/hr

Loading hopper: 500 x 500 mm

Crushing chamber: 500 x 190 mm

1st track: 500 x 130 mm (NEW)

2nd track: 500 x 190 mm (NEW)

Jaw adjustment: 9 levels [for each track]

Output size:

1st track → 0 – 40 mm

2nd track → 0 – 60/80 mm

Crusher and 4-Output Separator

500-200 M4

Overall dimensions: 1100 x 2750 x 2100h mm

Total weight: 1480 Kg

Electrical power: 7.5 kW – 380/400V – 50/60Hz

Productivity: 4 – 5 m³/hr

Loading hopper: 500 x 500 mm

Crushing chamber: 500 x 190 mm

1st track: 500 x 130 mm (NEW)

2nd track: 500 x 190 mm (NEW)

Jaw adjustment: 9 levels [for each track]

Output size:

1st track → 0 – 30/40 mm

2nd track → 0 – 60/80 mm

Screening (mm): 4 Customizable Separations

Accessories

Separation System M3

Permits the selection of the output in three customized parts

Tipping container C1

Useful for collecting materials, with superior grip

Tipping container C2

Useful for collecting materials,

with lower fork grips

Detection sensor X

Useful for conveyor belts’ automatic management

Conveyor belt PLUS

Ideal to transfer materials both at the inlet (crusher) and at the outlet (container).

Lateral Staircase K

Facilitates manual insertion of the material